Laboratory Testing

|

Research done by 'Norske Shell University' and many others, conclude that up to 80% of mechanical breakdowns are due to contaminated oil. Two measures must be taken to achieve optimum oil quality:

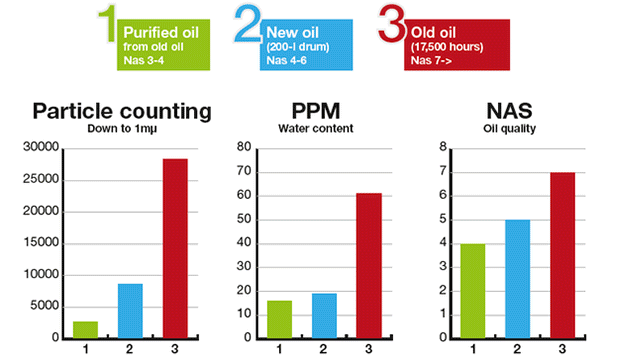

Particle contamination is a result of mechanical wear, dust, maintenance operations, defective gaskets, clogged filters, etc. Water contamination typically is a result of condensation, leaks into system, air valves or compressors or other equipment in the system. In addition to being corrosive, water may in high-pressured systems be highly abrasive on the internal surfaces of the equipment. The figures below show test results performed on oil with 17,500 hours of operation, compared to oil cleaned by Waagene Oil Purifiner and new oil. The results are clear, Waagene Oil Purifiner makes the oil better than new. Texaco Regal 68 Hydraulic Oil (17,500 Hours / 2 Years) Tests performed by Norsk Oljelaboratorium AS, May 2013 |

|